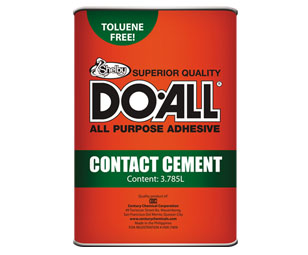

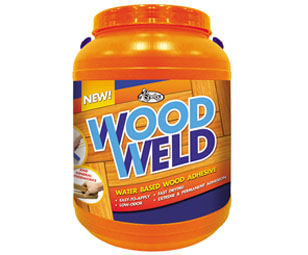

Adhesives

Automotive Paints

Polyurethane

Epoxy

Acrylic

Architectural Paints and Coatings

Hudson

- Hudson Surface Preparations

- Hudson Wood Coatings

- Hudson Concrete Coatings - Wall

- Hudson Wood and Metal Coatings

- Hudson Concrete, Wood and Metal Coatings

- Hudson Marine

- Hudson Special Effects Coatings

- Hudson Traffic Paint

- Hudson Roof Coatings

- Hudson Industrial Concrete Floor Coatings

- Hudson Industrial Metal Coatings

- Hudson Adhesive

Olympic

- Olympic Roofing Paint

- Olympic Wood and Metal Coatings

- Olympic Wood Coating

- Olympic Concrete Coatings

- Olympic Thinners

- Olympic Miscellaneous

Centro

Adhesives and Sealants

Cleaners and Disinfectants

Consumables

Special Products

back

TYPE:

Shelby #15 Concrete Weld Bonding exhibits excellent compatibility with inorganic binders in mortar mixes. It produces no undesirable effects on freshly prepared solid mortar. It is the most adequate material to use just before plastering concrete walls and for the repair of concrete structures or concrete patching. The bond strength generally is higher than the tensile strength of the majority of materials and is up by 15 to 25%.

USE:

Cement or concrete can be fortified by mixing them with Shelby Concrete Weld Bonding. The resulting material presents additional toughness, elasticity and greater ability to withstand shock, impact and abrasions. Also, resistance to the action of grease, acid and alkali is greatly enhanced.

SURFACE PREPARATION & APPLICATION:

Surfaces should be clean, dry and free from grease and oils. For plastering over concrete surfaces, brush the concrete surface with Shelby Concrete Weld and allow to stand approximately 10 to 15 minutes or until it becomes tacky, then apply the wet plaster mixture to the treated surface. When plastering is completed, it can then be left to set-up, and the result will be permanent. For patching concrete floors, apply a primer coat of Shelby Concrete Weld to the floor where the patch should be. Patch Mixture is 1 bag of Portland Cement, 3 cubic feet of sand, 1 gallon of Shelby Concrete Weld and enough water to obtain the right consistency.

SPECIFICATIONS:

Base : Resin Emulsion • Color : Milky White • Viscosity : 25 seconds Ford Cup #4

SPREADING RATE:

Plastering over concrete = 300-350 square feet / 4 liter. •Over the concrete before plastering = 450 square feet / 4 liter. •For obtaining maximum strength as admixture, use 1 liter of Shelby Concrete Weld to the following mixture: 1 bag cement, 2 cubic feet of sand, 3 cubic feet of gravel ( crushed at 3/4"), enough water

THINNING:

Water.

PACKAGING:

4 liter can.

(02) 8365 2618-21

(02) 8365 2618-21 inquiry@centurychemicals.com

inquiry@centurychemicals.com