Hudson

- Hudson Surface Preparations

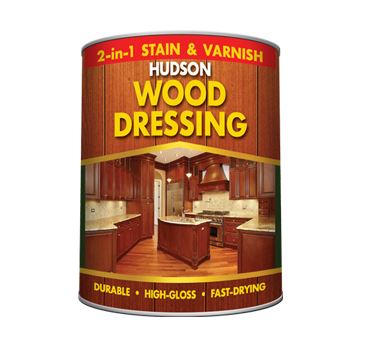

- Hudson Wood Coatings

- Hudson Concrete Coatings - Wall

- Hudson Wood and Metal Coatings

- Hudson Concrete, Wood and Metal Coatings

- Hudson Marine

- Hudson Special Effects Coatings

- Hudson Traffic Paint

- Hudson Roof Coatings

- Hudson Industrial Concrete Floor Coatings

- Hudson Industrial Metal Coatings

- Hudson Adhesive

Automotive Paints

Polyurethane

Epoxy

Acrylic

Architectural Paints and Coatings

Hudson

- Hudson Surface Preparations

- Hudson Wood Coatings

- Hudson Concrete Coatings - Wall

- Hudson Wood and Metal Coatings

- Hudson Concrete, Wood and Metal Coatings

- Hudson Marine

- Hudson Special Effects Coatings

- Hudson Traffic Paint

- Hudson Roof Coatings

- Hudson Industrial Concrete Floor Coatings

- Hudson Industrial Metal Coatings

- Hudson Adhesive

Olympic

- Olympic Roofing Paint

- Olympic Wood and Metal Coatings

- Olympic Wood Coating

- Olympic Concrete Coatings

- Olympic Thinners

- Olympic Miscellaneous

Centro

Adhesives and Sealants

Cleaners and Disinfectants

Consumables

Special Products

back

WHY USE HUDSON TIMBERCOAT?

Hudson Timbercoat is a one component waterborne non- yellowing urethane coating ideal for finishes on wood and parquet floors. It combines excellent hardness and flexibility, high abrasion resistance and high gloss appearance. It resists ordinary household detergents, acids and alkalis, sauces, food spills, and beverages and has very minimal odor.

- One Component

- Eco-Friendly (Low VOC)

- Mild Odor

- Non-Flammable

- Faster Drying or Curing Time

- Less Yellowing

TYPE

Hudson Timbercoat is a one component waterborne non-yellowing urethane coating ideal for finishes on wood and parquet floors. It combines excellent hardness and flexibility, high abrasion resistance and high gloss appearance. It resists ordinary household detergents, acids and alkalis, sauces, food spills, and beverages. Gives out mild odor.

USE

Excellent on wooden floor parquets for residences and offices. Also for interior and exterior wood such as furniture, store fixtures, cabinets, doors, and panels.Timbercoat is highly recommended for offices, commercial or residencial spaces, and condominiums (especially units that prevent the use of strong odor solvent base paints).

AVAILABLE FINISHES

Gloss, Semi-Gloss, Matte

APPLICATION CHARACTERISTICS

Clarity: Clear when dry.

Leveling: Excellent

Drying time: 1-2 hours

Maximum Cure: 100 % after 1 week

Gloss Level (60 degree): > 85 for GLOSS, 45-50 for SEMIGLOSS, 10-30 for MATTE

Odor: Mild odor

PHYSICAL CHARACTERISTICS

Color: White or slightly hazy liquid

pH: 8

Solids: 33-35 %

Viscosity (Ford Cup no 4 @ 29 C) : 20-25 seconds

Density: 8.61 lbs/gal

VOC Compliant

APPLICATION

By brush or spray.

COVERAGE

Coverage: 35-45 sqm /3.5L or 10-13 sqm L at 25-30 microns = 1 coating

CURING

• 1 day = 70% cured

• 3 days = 90% cured

• 7 days = 100% cured

SURFACE PREPARATION

1. Sand and prepare floor using 80-100 grit sand paper.

2. Make your final sanding with 400 grit sand paper.

3. Vacuum floor thoroughly and wipe with a dry cloth.

PAINTING NEW FLOORS

1. Shake container for I5 to20 seconds, then apply first coat.First coat acts as a sealer.

2. Let it dry for an hour then sand.

3. Apply another coat.

4. Sand after an hour.

5. Apply two more coats.

6. Allow 48 hours drying time for areas with light traffic and at least 7 days for normal to heavy traffic areas.

REPAINTING PREVIOUSLY COATED FLOORS

IMPORTANT! Be sure floor is free from wax, and oily residues.

1. Always prepare a sample or test area.

2. Make sure to clean the test area and sand it thoroughly before applying Timbercoat.

3. After 24 hours scratch the surface with a coin.

4. If adhesion still not ok after 3 days then the surface cannot be overcoated.

5. After ensuring that the floor is in order and adhesion is ok, clean the surface well and proceed to coat the whole surface.

IMPORTANT REMINDERS

• Do not use Timbercoat over alkyd-based wood filler, alkyd based wood stains, and some Latex Paints.

• Tannin naturally appear on some wood species. Finish results may vary depending on wood species.

PACKAGING

3.5 Liters

ABRASION

• Sanding is not necessary in between coats, except for first coat as sealer.

• It is not necessary to abrade between coats unless more than 48 hours has passed since the previous coat was applied. Always vacuum and wipe thoroughly with a slightly water-damped cloth after abrading.

CLEAN UP

Application tools should be cleaned with water.

FLOOR CARE

Put walk off mats at all entrance doorways to keep out excessive dirt and grit. Sweep or vacuum daily and damp wipe as needed.

CAUTION

Toxic and flammable. Keep away from fire and reach of children.

(02) 8365 2618-21

(02) 8365 2618-21 inquiry@centurychemicals.com

inquiry@centurychemicals.com

-1518413573207.jpg)